Copyright © Zhuhai Yuhong Agricultural Technology Co., Ltd. All Rights Reserved. Site Map

- +86-13924703810

- 13829089069@163.com

- 3rd Floor, Building 2, No. 128 Chuangxin 3rd Road, Tangjiawan Town, High tech Zone, Zhuhai City, Guangdong Province

Modern livestock and poultry farming is developing rapidly towards scale, modernization and informatization. The breeding environment has also become an issue that cannot be ignored. It directly affects the production efficiency and health of livestock and poultry. Monitoring various environmental factors in livestock and poultry houses has become a basic requirement for modern breeding.

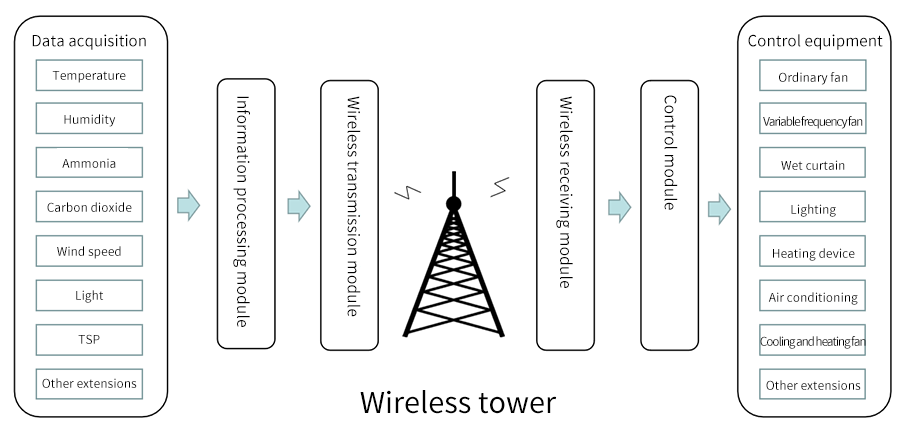

Intelligent environmental controller is a key technical means for livestock and poultry farming to improve breeding efficiency and economic benefits, ensure livestock and poultry health, and reduce resource waste and environmental pollution. It deeply integrates technologies such as artificial intelligence, the Internet of Things and big data analysis with livestock and poultry farming production, making it a key step in the transformation of traditional livestock and poultry farming to modern livestock and poultry farming. The intelligent environmental controller is a system that integrates monitoring and control. It uses sensors to remotely monitor various environmental factors in the house, transmits the monitoring data to the control terminal through a computer, analyzes the data and makes corresponding controls to adjust the environment of the livestock and poultry house. The principle block diagram of the system is shown in Figure 1. Compared with the intermittent, lagging and subjective nature of traditional manual monitoring and control, intelligent environmental control can continuously, quickly and accurately monitor and control the livestock and poultry breeding environment, providing a healthy and comfortable house environment for livestock and poultry growth.

Developed countries such as the Netherlands, Israel and the United States began to develop livestock and poultry environmental monitoring systems in 1970. On this basis, they integrated disease diagnosis, feeding and automatic manure cleaning systems to form an intelligent breeding management system, which has been applied in modern farms. The research on livestock and poultry house environmental monitoring systems in my country started late. From the "Eighth Five-Year Plan" to the "Thirteenth Five-Year Plan", a few large farms achieved automated or semi-automated control, but they were still limited to single-function environmental control equipment, which could not meet the complex environmental regulation needs of livestock and poultry houses. There was a lack of overall research and there was still a gap to achieve intelligent environmental control. However, after Internet technology giants such as NetEase and Alibaba entered the pig farming industry, they are expected to subvert the traditional pig farming industry and promote industry reform and upgrading, which will bring new opportunities for the development of intelligent environmental monitoring and control of livestock and poultry houses in my country. This article introduces the research progress of intelligent environmental control of livestock and poultry houses from the perspectives of data acquisition, data processing, data transmission and control theory, and provides a reference for its further application in the livestock and poultry industry.

The data collected on site of livestock and poultry houses mainly include temperature, humidity, ammonia, carbon dioxide, wind speed, dust, light, etc. As early as 1988, Seedor et al. arranged temperature and humidity integrated sensors in livestock and poultry houses to collect temperature and humidity data. Phillips et al. arranged sensors at 7 different locations in livestock and poultry houses to monitor environmental parameters, and set a general method for the quantitative emission of pollutants in livestock and poultry houses. Ni et al. collected ammonia concentration data in pig houses, and constructed a mathematical model of ammonia volatilization in pig houses by fitting data curves, which laid a theoretical foundation for the regulation of ammonia concentration in houses. Andonov et al. collected temperature and humidity data under natural ventilation and air conditioning control in different seasons, and proposed a new natural ventilation control method. Kim et al. studied the spatial distribution of heat and the content of dust particles in the air in closed pig houses in winter, and found that the dust content in pig houses was closely related to the air temperature and humidity in pig houses. Daskalov et al. collected airflow data in pig houses in winter and summer, and proposed a nonlinear adaptive correction algorithm based on the joint control of air velocity, temperature, humidity and flow direction in pig houses, which is of great significance for guiding pig production. Banhazi et al. collected environmental data such as bacteria, inhalable particles and harmful gas concentrations in 160 piggeries. The study found that appropriate environmental improvement strategies can reduce the concentration of air pollutants in the piggery environment.

Wireless sensor network technology is mainly used to monitor various environmental parameters in modern animal husbandry. For example, Chen Junjie, Wang Ran et al. realized real-time monitoring of livestock and poultry environmental parameters based on wireless sensor networks. Kang Ruijuan et al. studied data transmission methods based on beef cattle breeding information collection. Liu Pingzeng et al. designed a livestock and poultry scale breeding environment information collection system, studied and designed a variety of environmental parameter detection modules, and found that the system was stable and reliable with high detection accuracy after application. Hwang et al. established a piggery environmental monitoring system, which analyzes the collected environmental data and ultimately controls the operation of environmental control equipment. Wang Leiyu et al. studied the monitoring and early warning system for healthy livestock and poultry breeding environment, and realized real-time monitoring and early warning of the piggery environment. Shen et al. used the response surface method to model the natural ventilation and air exchange rate of dairy cow houses. Stinn evaluated and controlled the piggery environment through long-term experimental monitoring data.

Single-chip microcomputers and PLCs play a major role in environmental monitoring systems. Single-chip microcomputers can be embedded in various instruments and equipment. For example, the environmental monitoring system developed by Peng Jiansheng et al. uses the ADuC824 single-chip microcomputer as the core chip, which can collect data efficiently and in real time, with fast response speed and high sensitivity. Dai Chunxia uses the C8051F020 single-chip microcomputer as the core and Modbus bus for on-site networking to measure and automatically control the environmental factors of the pig house. However, the failure rate of single-chip microcomputers is high, programming is becoming more and more complicated, and the development cycle is long. Therefore, embedded ARM chips with high performance, low price and strong scalability are generally used for data processing. Ma Liang et al. used PIC single-chip microcomputers and TCP/IP network protocols to implement embedded Web servers to develop a chicken house network environmental parameter monitoring system, and administrators can monitor the environmental information of the chicken house in real time. Familiarity with embedded operating systems requires high professional literacy.

PLC programming is simple, functional, and the workload of later maintenance is small. For example, Yu Mingzhu et al. realized automatic temperature control of piglet houses based on PLC. Guan Mingjie developed a PLC distributed control system, which collects various environmental parameters through sensors and adjusts the environment through equipment such as fans and water pumps. Lu Yu and others used PLC to realize intelligent control of pig house environment. However, the hardware systems of various PLC manufacturers are independent of each other. Users must first select the PLC model and then learn the corresponding control procedures and programming languages.

At present, the most widely used wired communications in livestock and poultry houses and greenhouses are RS485 bus and CAN bus. Short-range wireless communications include Bluetooth, wireless LAN (Wi-Fi), infrared digital link (IrDA), wireless personal area network near field communication (NFC), Zigbee, and ultra-wideband (UWB). The characteristics of each communication protocol are shown in Table 1. For example, Ma et al. developed an intelligent control system for pig growth environment based on CAN bus. Wu et al. developed a chicken house intelligent environment control system based on ARM and ZigBee technology to realize remote monitoring of chicken house environment. Mao Deping et al. designed a distributed data acquisition and control system that can achieve longer distances through RS-485 bus. Zhou Liping and others used mobile inspection vehicles and Wi-Fi to collect environmental data from all over the pig house. Zhou Chenfei designed an intelligent pig house environment collection system based on Zigbee, which can be viewed remotely through a computer. Li Li and others used ZigBee to design an environmental sensing system, and adjusted the temperature and humidity through a central server to provide pigs with a suitable temperature and humidity growth environment.

The combination of hardware and software makes the environmental control system more stable and efficient. For example, Xie Qiuju and others set up sensor terminal nodes, single-house control nodes and ZigBee coordinators based on the CC2430 chip to combine more sensor data with computing devices, so that environmental data can be collected and transmitted to the control center. Shen Chen and others used the CC2530 module as the hardware core to form a wireless communication technology node, used ZigBee wireless communication technology to achieve transmission, and used the MSP430 microcontroller as the core processing unit to process data and control peripheral components to regulate the environment in the poultry and livestock house. Niu Haichun and others used TM32 microcontroller as the main control chip, Liang Tianhang and others used ZigBee technology, PLC technology and sensor technology to monitor the pig house environment in all directions, compared the collected data with the system reference data, and reasonably controlled the electrical mechanism to regulate the environment of large pig houses.

Ma Jiqing and others used ZigBee networking to receive environmental parameters at each collection point, RS485 technology data transmission, and communication between PLC and RS485 to achieve real-time remote monitoring of environmental factors inside livestock and poultry houses, and process the information. Through the corresponding thresholds set by the terminal software, the manual/automatic control conversion of the equipment in the house is realized to obtain the most suitable environment for livestock and poultry growth.

The development of science and technology has helped the research and development and application of livestock and poultry house environmental monitoring systems. Various excellent algorithms can solve practical problems of environmental monitoring and control. For example, Yu Shouhua and others effectively reduced the interference of various harmful gases by combining genetic algorithms with wavelet transforms, and improved the accuracy of gas monitoring data. In order to overcome the uncertainty and instability of single sensor monitoring, Teng Cuifeng and others integrated the adaptive weighted fusion algorithm with the D-S evidence reasoning theory to achieve multi-sensor data fusion. Cui Herui et al. completed the software and hardware implementation methods of environmental monitoring of livestock and poultry houses under fuzzy control conditions and discussed the practicality of fuzzy control systems. Liu Pingzeng et al. developed a livestock and poultry breeding environment control system based on fuzzy control algorithms. Qian Dongping et al. used fuzzy control theory to monitor the temperature of livestock and poultry houses in real time, established a mathematical model for temperature control and monitoring of livestock houses, and increased the stability of the temperature control process. Zhao Jingwei et al. used fuzzy control algorithms to control pig house environmental control equipment, water pumps and fans. In order to solve the problem of heat preservation and ventilation control of pig houses in cold winter, Xie Qiuju et al. designed a closed pig house multi-environmental factor control system based on fuzzy control algorithms.

Intelligent environmental control is an important foundation for digital innovation and sustainable development of my country's livestock and poultry breeding industry. The current idea of the environmental control system is to obtain various environmental parameters (temperature, humidity, ammonia, etc.) in livestock and poultry houses through sensors, and transmit them to the control center of the system through data processing and data transmission. After analyzing and summarizing the collected environmental data, the control center issues corresponding operation commands to each environmental parameter control terminal device (fan, wet curtain and lighting, etc.), so that it controls the corresponding on-site equipment and realizes automatic environmental control of livestock and poultry farms. However, the environment of livestock and poultry houses is complex and changeable, and environmental control technology still faces many problems and challenges. Although the intelligent environmental control system for livestock and poultry has undergone years of research and development, the relevant technical standards have not been fully popularized and applied, which greatly restricts the promotion and application of intelligent environmental control for livestock and poultry. The full popularization of intelligent environmental control is the only way for the large-scale, digital and technological transformation and upgrading of the livestock and poultry farming industry.